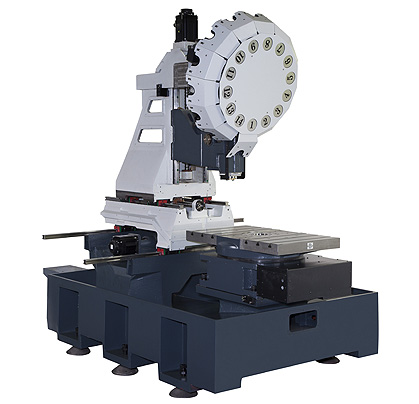

Pionowe 2-paletowe

Trident TS-45 Series

Materiały do pobrania

- No files to download

– Standard spindle speed 10,000 rpm (BT#30)

– Three axes rapid traverse 48/48/48 m/min

– High speed tool change

– Rigid tapping 4,000 rpm (BT#30)

– Spindle tapper BT#30

– Direct-drive spindle

Standard Machine Features

– Spindle air blow device.

– Double PL lights for working area and parts change area.

– Tool coolant system and big flow chip flushing system.

– Pressure detected automatic lubrication system and precision lubrication oil filter.

– LED high brightness dual-color alarm light.

– One-piece double layer heat isolated electric cabinet.

– Tool kits and tools.

– Table with twin working area.

– Pneumatic type table distributor. Each working area is equipped with one set of air circuit

Optional Accessories

– High speed spindle BT#30, 24000 rpm.

– Extra low inertia spindle motor.

– Increase motor power.

– High pressure coolant through spindle.(20 BAR)

– Automatic tool length measurement with breaking detection.

– 4th axis rotary table (for both working tables also).

– Thermal compensation system.

– Transformer, regulator.

– Connetcion for table-hydraulic

– Three axis linear scale

– Chip conveyor-rear type (filter / scraper / chain type)

Working Table Size

Dimensions

Machine Specifications

|

Model |

TS-45 | |

| TRAVEL | ||

| X-Travel | mm | 450 |

| Y-Travel | mm | 320 |

| Z-Travel | mm | 320 |

| Table to Spindle Nose | mm | 180~510 |

| TABLE | ||

| Table Area | mm | 500x325x2PCS |

| Max. Load | kgs | 200x2PCS |

| T-Slot | mm | 14x100x3 |

| SPINDLE | ||

| Spindle Speed | rpm | 10000 |

| Max. Tapping Speed | rpm | 5000 |

| Spindle Taper | mm | 7/244 NO:30 |

| Transmission | mm | Direct Drive |

| TRAVERSE | ||

| Rapid Traverse (G00) | M/min | 48/48/60 |

| Machining Speed (G01) | mm/min | 10000 |

| MAGAZINE | ||

| Tool Shank | . | BT# 30 |

| ATC | . | Armless |

| Magazine Capacity | . | 14 |

| Max. Tool Length | mm | 200 |

| Max. Tool Diameter | kgs | 100 |

| Max. Tool Weight | sec | 2.5 |

| Time (T to T) | sec | 1.5 |

| Time (C to C) | sec | 2.1 |

| MOTOR | ||

| X-Axis | kw | 2.2(Mitsubishi) / 1.8(Fanuc) |

| Y-Axis | kw | 1.5(Mitsubishi) / 1.8(Fanuc) |

| Z-Axis | kw | 2.2(Mitsubishi) / 3.0(Fanuc) |

| Spindle | kw | 3.7/2.2 |

| MACHINE SPECIFICATIONS | ||

| W x D x H | cm | 1755x3027x2523 |

| Net Weight |

kgs |

4000 |

NC Specifications

| Mitsubishi | Fanuc | ||||||

| M70-VB | M70-VA | M80-VB | M80-VA | M720-VS | 0i-MF(P3) | 0i-MF(P1) | |

| CPU | 64 bit | 32 bit | |||||

| Max. Controlled Axes | 9 | 11 | 9 | 11 | 12 | 6 | 9 |

| Max. Simultaneous Axes | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Program Storage Length | 512K | 512K | 512K | 512K | 512K | 512K | 512K |

| Macro Variables Common | 700 | 700 | 400 | 400 | 700 | 700 | 700 |

| Tool Offset Sets | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Conversational Programming | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Display | 8.4″ TFT LCD | 10.4″ TFT LCD | 8.4″ TFT LCD | ||||

| Mulit-Language Display | 0 | 0 | 0 | ||||

| Servo Motor with ABS. Encoder | 0 | 0 | 0 | ||||

| Memory Card Front-Loading | 0 | 0 | 0 | ||||

| Ethernet | 0 | 0 | 0 | ||||

| High Speed And Accuracy Machining Code | G05.1 Q1 | G05 P10000 | G05 P10000 | SSS | SSS | G05.1 Q1 | |

| RS-232 Interface | 0 | 0 | |||||

| Toolpath Simulation | 0 | 3D | 0 | ||||

| Handwheel Feed Program Simulation | 0 | X | |||||

| Program Buffer Correction | 0 | X | |||||

| ○ Standard × None |